Heating Bulk Solids Using Steam, Hot Water or Thermal Oil

Slow & Controlled Product Flow

Bulk solids pass slowly downward between a series of vertical hollow heat exchanger plates.

Indirect Plate Heating

Heat transfer media, such as steam, hot water, or thermal oil, flow through the plates to heat the bulk solids material by conduction.

Mass Flow Technology

The mass flow discharge feeder creates uniform product velocity through the cooler and regulates the product flow rate.

Vertical Configuration

Bulk solids pass through the vertical cooler by gravity.

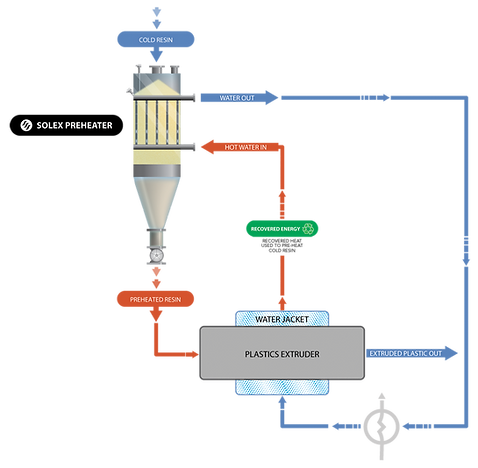

PreHeating Resin Using Recovered Hot Water

Heating Bulk Solids with Recovered Exhaust Gases

Uses Up To 90% Less Energy

The Solex bulk solids heater is ultra-efficient, using up to 90% less energy than other technologies.

Precise Final Product Temperatures

The mass flow design of the Solex heater means the product moves with uniform velocity through the heat exchanger.

To Find out more about Solex Thermal Cooling System, please click HERE